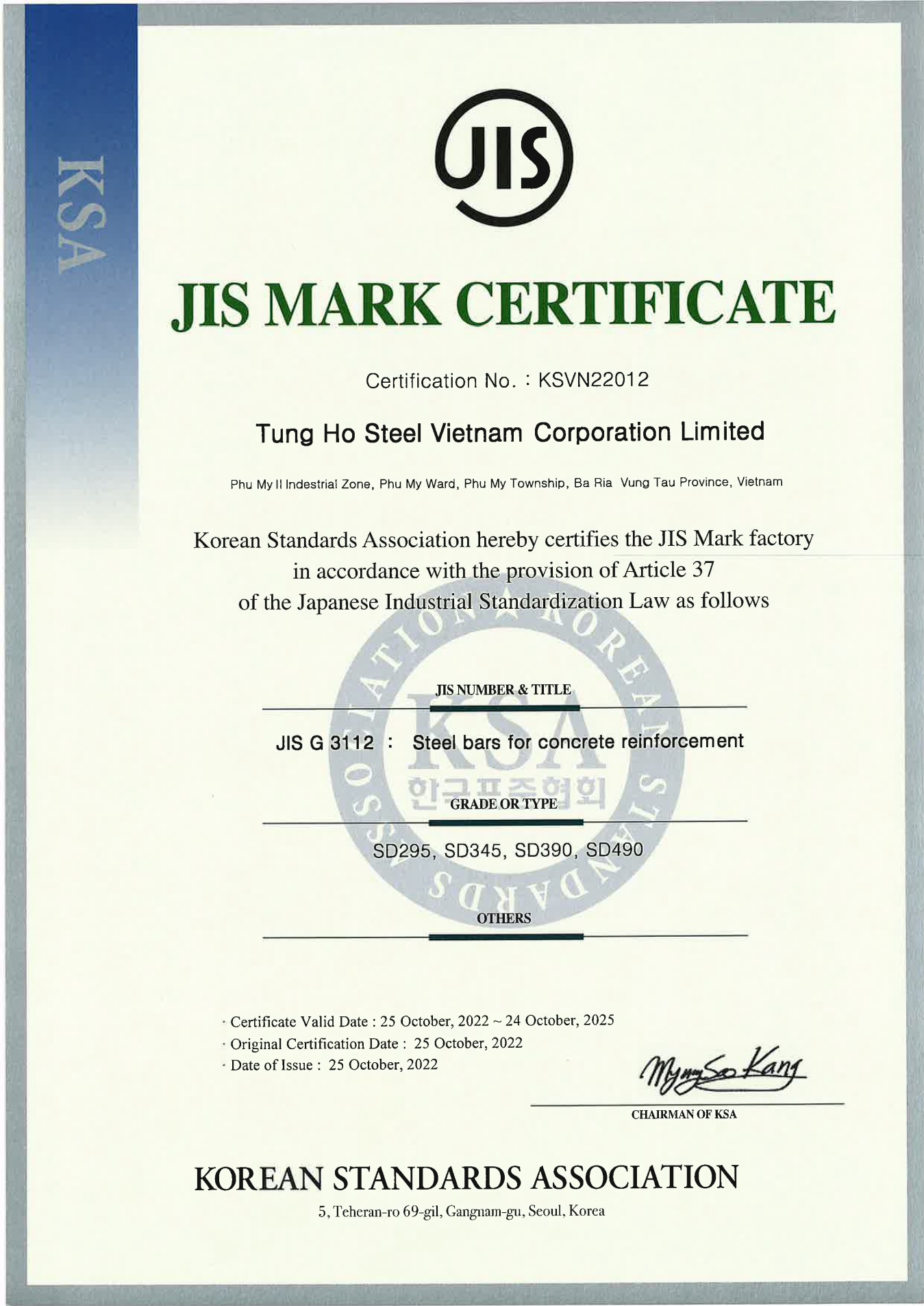

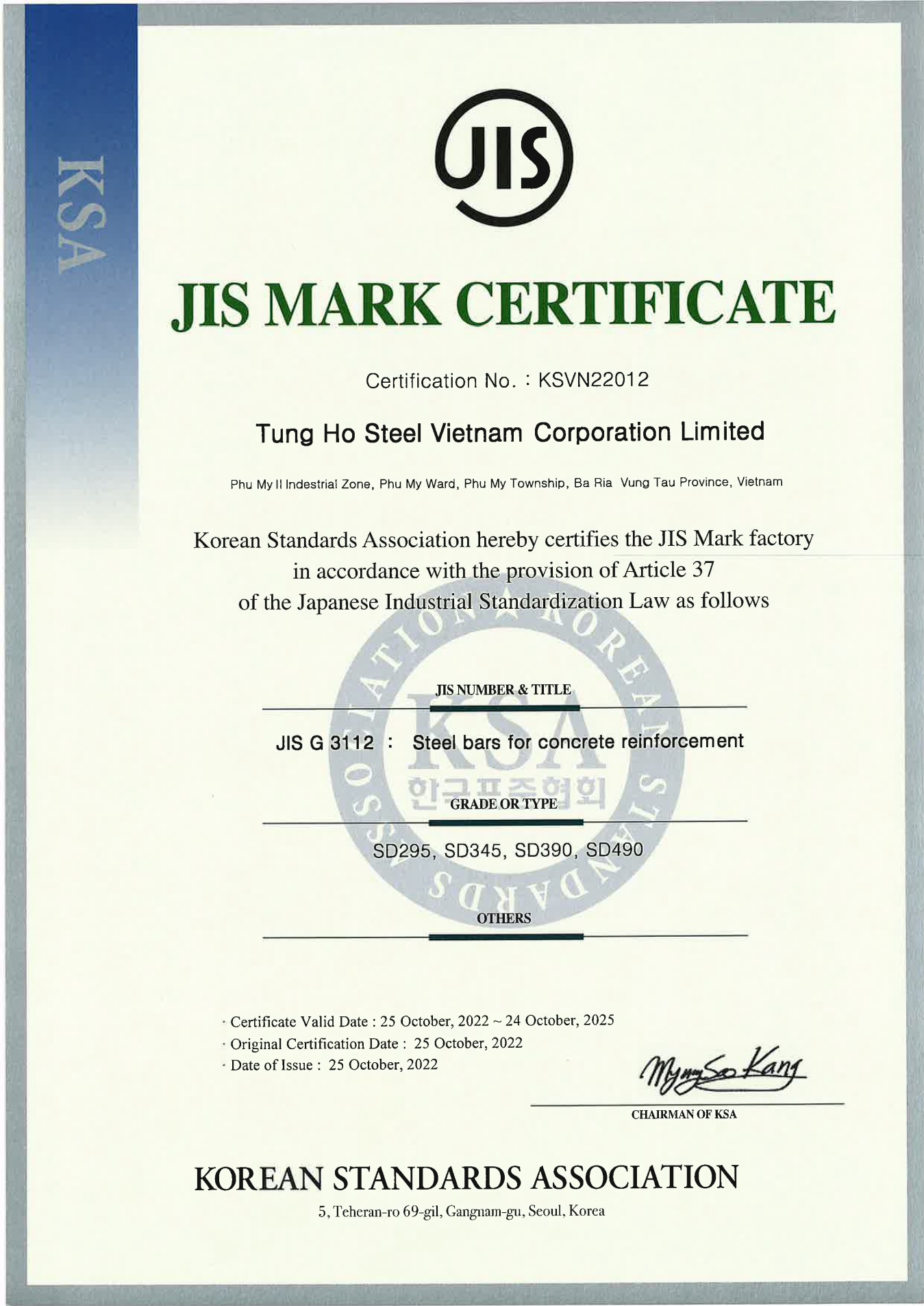

Tung Ho Steel Vietnam (THSVC) obtained the deformed bar KS MARK certificate issued by Korea KSA on November 23, 2022

Certified steel grades: SD300, SD400, SD500, SD400W, SD500W, SD400S, SD500S

Approved size: D10~D51

More Activities

Certified steel grades: SD300, SD400, SD500, SD400W, SD500W, SD400S, SD500S

Approved size: D10~D51