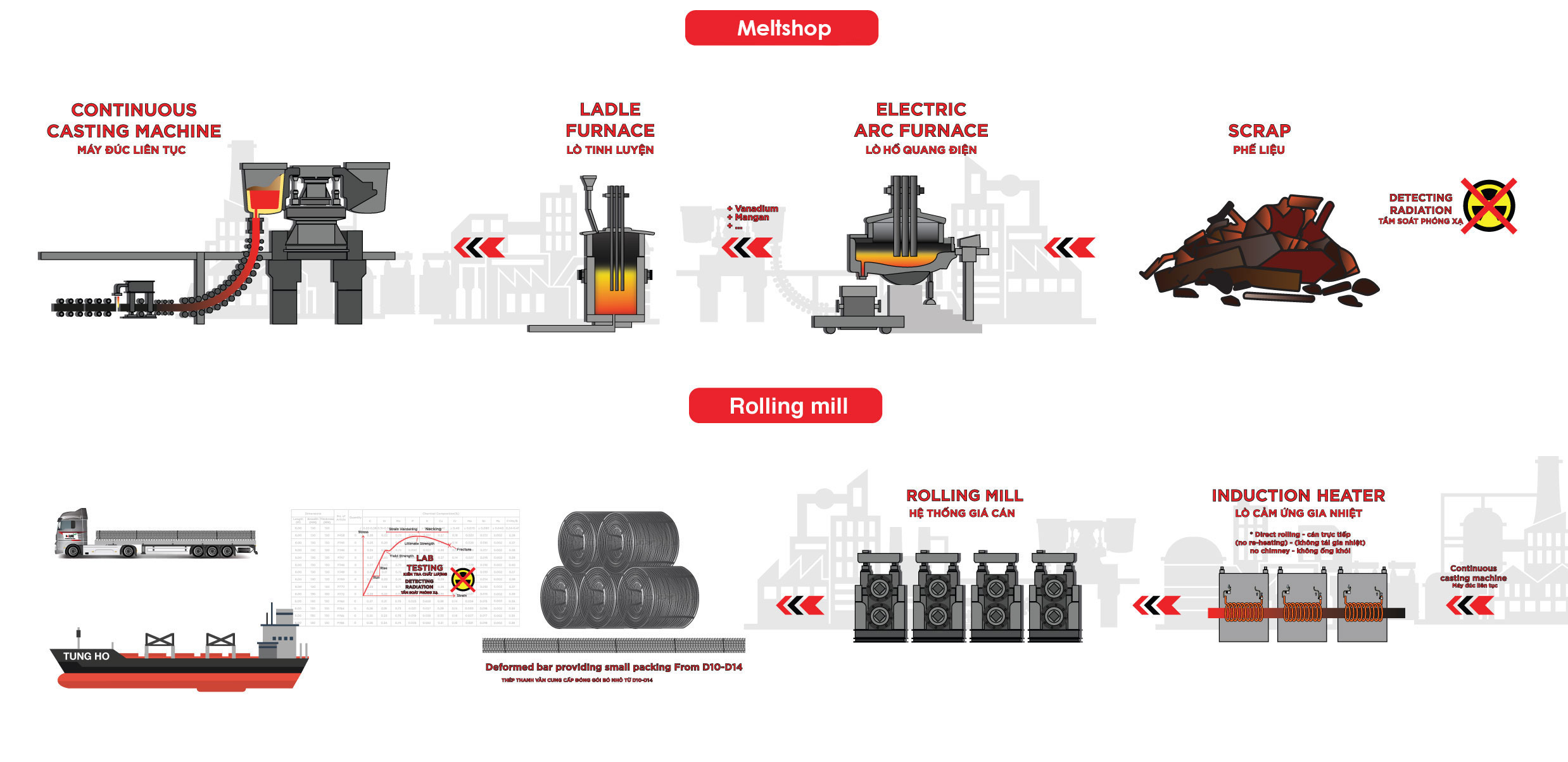

At present, THSVC only engages in steel refining. We are in the process of modifying our casting equipment and creating a rolling extension. Thanks to this modification of our casting equipment, the billets we cast in the future will reach 850 degrees Celsius. The hot billets will be sent directly into an induction heater for surface heating to give the billets a uniform internal and external temperature. Combined with the rolling mill now being built, this will result in the most optimized configuration for refining and rolling production lines and in better equipment performance. The result will be the world's most advanced direct rolling process. The time it takes for the raw material to enter the plant and become rebar will be shortened from the traditional three-plus hours to two hours or less, and maximum production capacity will reach 155 tons per hour, dramatically raising productivity. We are set to become a specialized rebar production plant that gives as much weight to energy conservation and environmental protection as to productivity.

Manufacturing Procedure